Our Products

-

- ARC Roof

- Saddle Roof

- Tunnel Roofs

- Pitch Roofs

Why Tiger Truss

- Tiger Truss is one of the leading suppliers of aluminium truss systems on the international market

- Efficient and modern production technology

- Superb fast conical connection system

MORE INFORMATION?

Got a question about our products or services? Please contact our sales department:

- info@tiger-truss.com

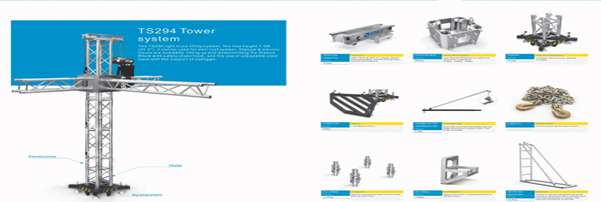

The LL35S Tower makes an excellent vertical truss that allows the safe and quick lifting of regularly loaded horizontal Mega Span Truss Rig and Roofs to their service height. In terms of static, the LL35S Tower is designed for a high flexural and pressure strain. Especially when used in Roof Systems, this high flexural strain is required.

LL35S Tower Truss is a square 35cm heavy duty truss with one side integrated horizontal bracing for safe and easy climbing.

FACTS

- Suitable for use with 1t electrical chain hoist

- Steel Base equipped with high quality cast wheels

- Sleeve Block made out of a Aluminium alloy corner block

- Up to 14 meters

TECHNICAL SPECIFICATION

- Height: 350mm

- Width: 350mm

- Main Tube: 50×3 mm

- Sub Tube: 50x2mm

- Braces: 25x2mm

- Material: EN-AW-6082 T6

Top Section & Sleeve Blocks

The LL35S Top Sections come with running wheels and can accommodate either manual or electrical chain hoists. Additionally, the top section serves as a dead-hanging point. LL35S Sleeves are compatible with different attachments and are suitable for various types of trusses. These Sleeve Blocks are sturdy and secure, featuring dimensions carefully chosen to seamlessly integrate with standard truss elements and corners.

Hinge set

A strong, safe and cost-effective solution to erect the LL35S Tower. The Hinge Sets are 120 mm long. The half connectors with a hinge fork allow a very high vertical load. There is always 4 pcs Hinge Sets required per tower, 2 left and 2 right versions.

Base section & Outriggers

Steel Base on wheels available with Short Outriggers and Long Outriggers in combination with Stabilizer Bars.

Ballast Base

This is an alternative base frame which is an engineered steel flexible frame to the base to put ballast on. Solid wheels enable you to transport the ballast easily, while spindle feet lock down the frame. Standard pallet sized ballast fit on the base frame to ensure the correct positioning of the ballast.

Erecting System

This easy and fast tower frame, strapped with ratches to the main truss, can be used to erect the towers with just the help of an electrical chain hoist.